Army sees 3D printing taking off ‘very, very soon’

From printing thousands of drone “bodies” to hundreds of vehicle components, the land service sees a host of opportunities from additive manufacturing.

From printing thousands of drone “bodies” to hundreds of vehicle components, the land service sees a host of opportunities from additive manufacturing.

“Is it really the right answer to have a brigade carrying around 3D printers in the back of a truck trying to print 100, 400, 500 of these things at a time, and fabricate them while on the move so they don't get targeted by the enemy?” asked Col. Nick Ryan, director of the Army Capability Manager for Unmanned Aircraft Systems.

“We need to do it at a price point that is ridiculously low: We don't need the Gucci cameras and everything else,” said Army Futures Command head Gen. James Rainey.

“If you are a supplier, and your lead time is too long, and you refuse to work with us” on 3D printing alternative spare parts, said Rear Adm. Jon Rucker, “we're going to figure it out. Not a threat – a fact of life.”

The service has produced a battery bracket but is seeking manufacturing partners to design other components.

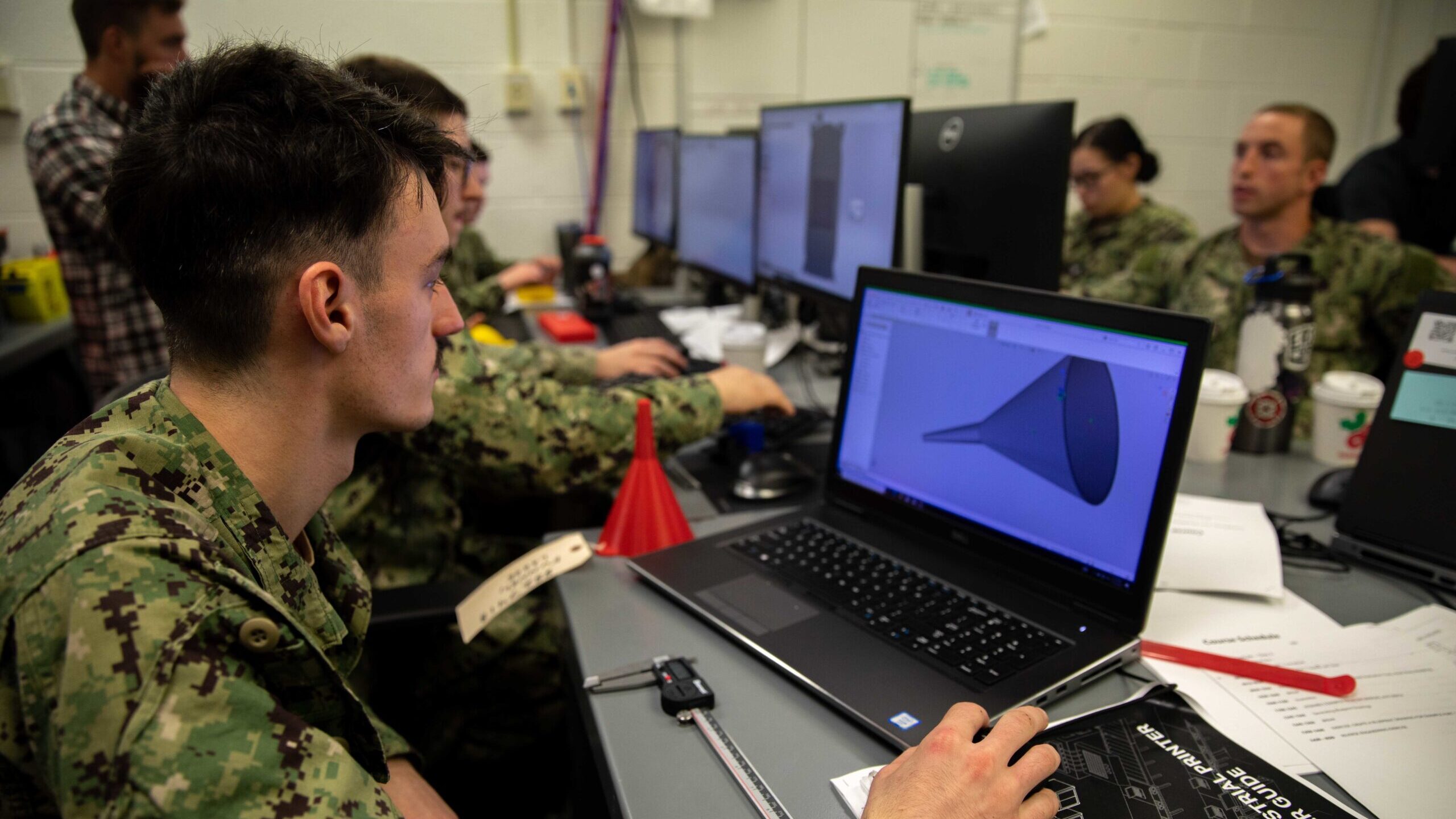

The proliferation of 3D printers, combined with loosened rules on using them, could change the way the Navy fixes its ships at sea, a top officer tells Breaking Defense.

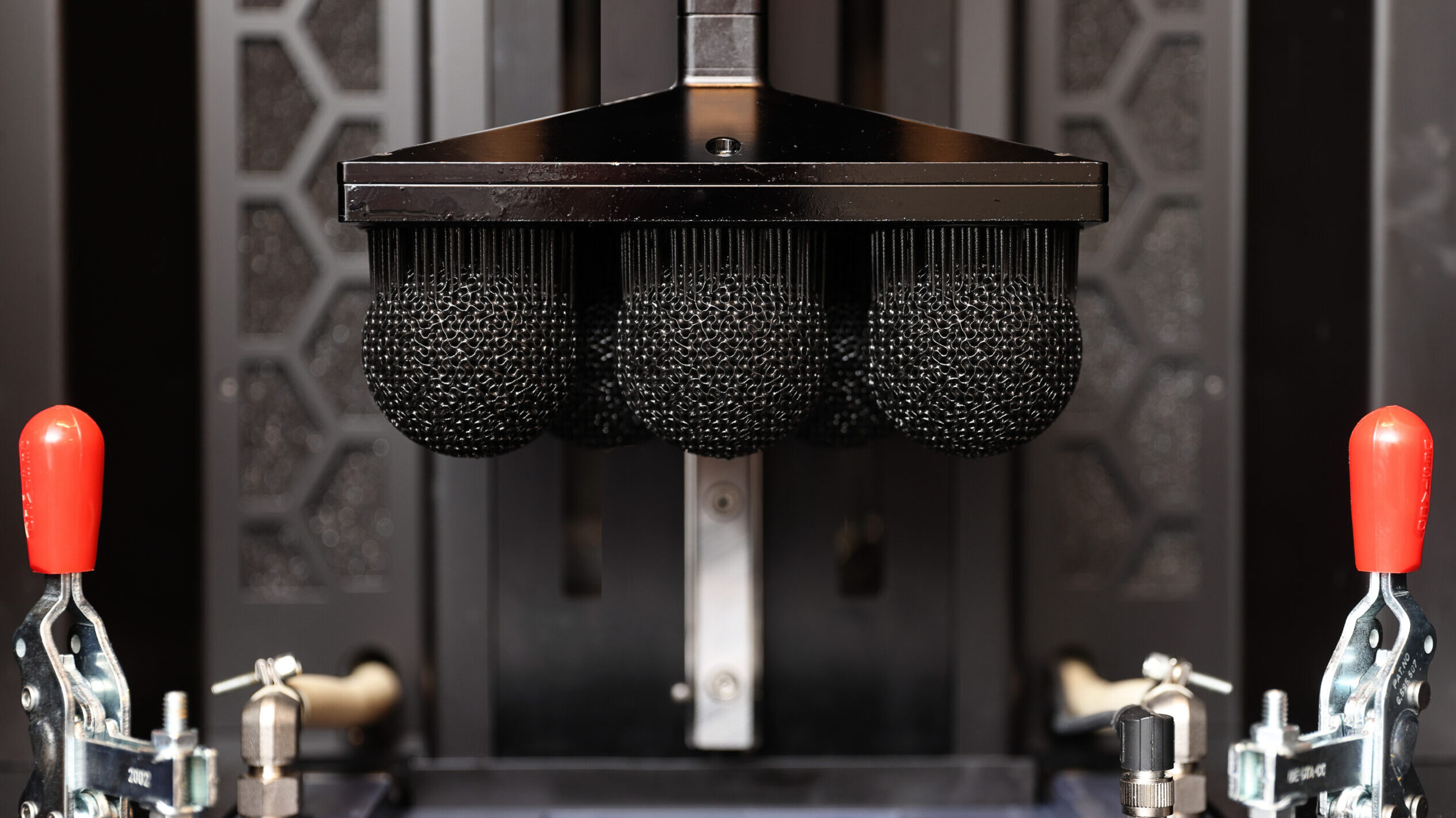

The company, just 55 employees strong, boasts a unique approach to additive manufacturing of lightweight, versatile composites well-suited to aerospace applications from fighter aircraft and drones to hypersonics.

An HII executive told Breaking Defense the NAVSEA certification will open the door for other alloys to be approved for use.

For something like a small UAS, “instead of taking years to develop [a design] it takes months, and instead of taking weeks to manufacture by laying out carbon fiber, we take hours to assemble," Divergent CEO Kevin Czinger told Breaking Defense.

The jump to metal-based 3D printing for Navy ships has been a long time coming, as the service wants quick fixes for commonly degraded parts.

Michigan’s defense ecosystem and expertise makes it a special asset for production.

3D printing satellites would allow the Space Force to rapidly "pivot" to meet new threats by compressing the time from design to orbit, says Millennium Space Systems CEO Jason Kim.

A Pentagon watchdog's new report brings together the services' lacking efforts in cybersecurity and ambitious strides in additive manufacturing.

"The ability to additively manufacture an aircraft engine part and gain military airworthiness is a significant step forward in growing the adoption of additive manufacturing in the Air Force,” Nathan Parker, deputy program executive officer at RSO, said.